Washing components and produced parts

The use of environmentally safe detergent INCONTTECH® in washing, flushing and degreasing operations does not require change of technology and redesign of existing washing machines operated in a closed cycle. Moreover, there is no need of additional rinsing to remove deposits which can distort measuring devices data and cause corrosion (as in the case of traditional detergents containing caustic soda).

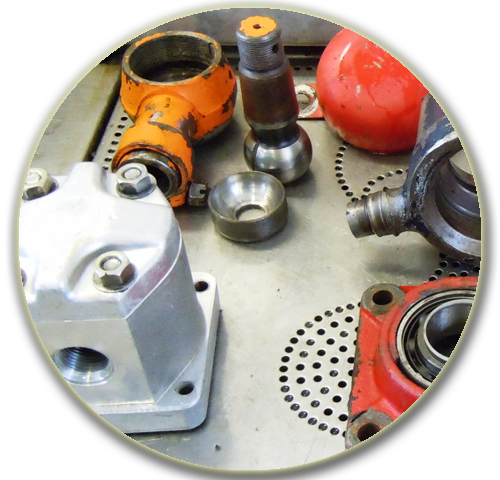

The use of INCONTTECH® is extremely effective in washing a whole range of patrs produced by the component manufacturers of different parts, made of metal, polimer, glass or rubber. INCONTTECH® does not cause oxidation and corrosion of surfaces being washed. The presence of passivating additives and antistatic agents provides protection of the surface of units and aggregates being washed from corrosion (passivation) for the long period.

INCONTTECH® detergent in combination with fully automated washing machines equipped with a cutter for removal of hydrocarbons separated during washing, can solve a lot of technological problems and to raise the quality of surfaces treatment. Hydrocarbons separated in washing process, are removed to a separate container for further utilization or selling to companies specializing in spent oil and lubricants reclamation.